The pharma manufacturing industry needs new and innovative ways to deliver more output, lower costs and increase sustainability. In short - they need to reach operational excellence. But where to start?

Due to the complicated nature of pharma manufacturing and its ever-changing landscape, challenges related to productivity and utilization are common. Finding solutions requires innovative and creative thinking, which is why our pharma engineering experts at NNE frequently combine design thinking and design sprints (a methodology created by Google Ventures) to find the right path for our customers.

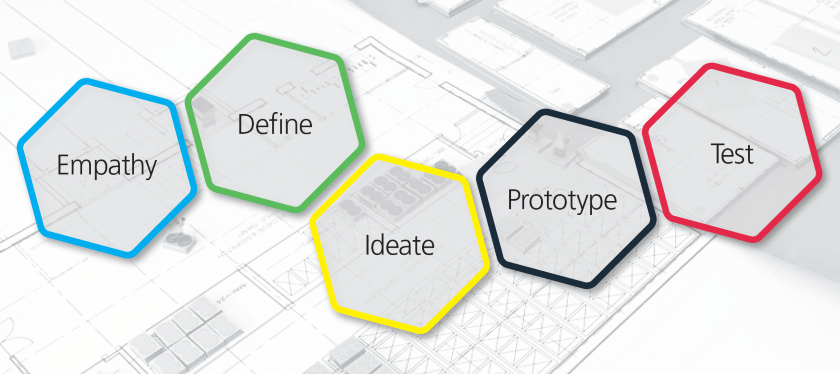

What is design thinking and how can it help with pharma manufacturing?

Design thinking is a systematic, customer-centered approach that builds creativity directly into development processes. It describes an iterative process that employs unique and creative techniques to yield results — usually results that exceed initial expectations. The 6 typical stages of the design thinking process are as follows:

Helping you reach operational excellence with data driven, sustainable solutions

The core of operational excellence is finding tailored solutions to your problems, helping you get the most out of your production. Design sprints are a fast and intense process for developing potential solutions, testing them out and learning what could work in just five days.

Depending on your challenge, we utilise these methods and our unique pharma manufacturing knowledge to help you piece together the right solution. This could include:

- Improving energy efficiency to help you reach sustainability goals

- Lowering Quality Control costs

- Lowering Full Manufacturing Cost per Unit (FMCU)

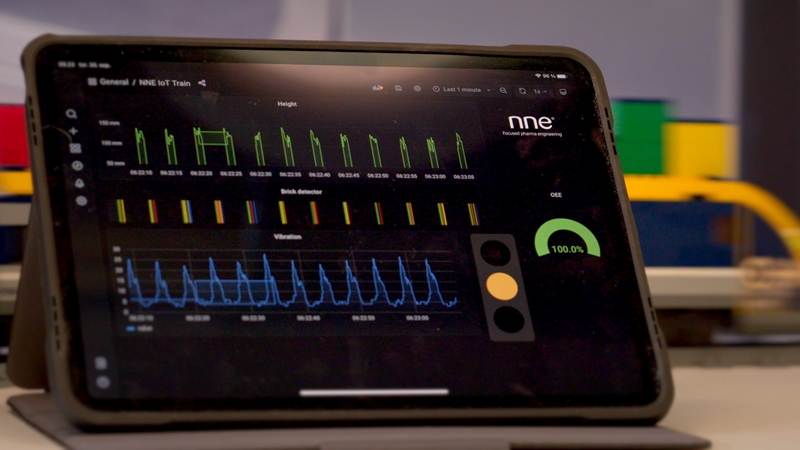

- Improving Overall Equipment Efficiency (OEE)

- Increasing data efficiency

By working together in a sprint, we shortcut the endless-debate cycle and compress months of time into a single week. Instead of waiting to launch a minimal product to understand if an idea is any good, we get clear data from a realistic prototype. Put simply, we fast-forward into the future to see a finished product before you make any expensive commitments.

I usually think of NNE as a company we call when we know what the task is. I had no idea that you could help define the problem and create potential solutions.”